Spray Equipment Safety Should Be Top Priority

Posted by Andrew Greess on Nov 16, 2021

There are a number of things discussed that you, as the boss or as the technician, can do to help prevent and minimize safety risks and equipment failure. Everyday before you leave, perform safety checks on the condition of your equipment. Check for any signs of leaks, wear on your hoses and fix any issues no matter how small, before you are on the job.

Technicians: Take time upon arrival of each new job site to check for obstacles, hazards and areas to avoid. Don't rush and cut corners, eventually all the short cuts that "saved you time" by not winding the hose reel carefully and allowing it to scrape along the lift gate will cost you a lot of time and potentially a safety situation.

Speak up to the boss if you see areas and equipment that might be on the verge of failure. Have a buddy whose company does it better way? Speak up and maybe you can change your procedures too!

Bosses: Listen to your employees. They are on the front line and using the equipment day in and day out. If they see a better way to organize equipment – hear them out, it might save them time and you money!

Learn from the example of others – see a smart layout of equipment in a rig, rearrange your trucks! Hear a nightmare scenario cause a tech didn't have a lock for their hose reel and they dragged the nozzle across town. Pause and think realistically if that could happen to one of your tech's, change your procedures for the better.

Hold safety meetings to hear employee concerns. Check over your spray rigs yourself regularly, it's nice to trust your technician's but maybe your standards and definitions of 'proper working condition' vary.

Safety should be a top priority. In our years experience, at least half of all equipment problems are completely avoidable.

" frameborder="0" allow="autoplay; encrypted-media" allowfullscreen="">

Andrew Greess: Summary. Good news is, I'm almost done. As a reward for staying awake, for any of you, because you're here at Metro Institute, take 25 bucks off your first order on our website, Qspray.com. Just use that code, Metro25.

We have a huge inventory of parts and equipment. I can give this to you after the class if you need it, but 25 bucks off your first order, I think is off a $50 order. You can do instore pickup, so there is no freight.

Summary. Safety, for the technician, for those of you who are technicians, here's what I want you to do. Number one, we talked about this. Inspect your equipment at the start of the day. If there's a leak, deal with it. Make sure it's secure. That's just such an easy one to do, it takes no time.

Don't rush, don't cut corners, and don't walk backwards. It's a lot more costly to the company if you have an accident than you trying to rush and do not as good a job. Steal ideas from meetings like this. Talk to your colleagues. Go out and look at the trucks in the parking lot. You don't have to invent every idea yourself, you just have to keep getting better.

This is a key one, and I hope all the technicians in the room will take this one to heart is don't live with problems. If you got chemicals spilling somewhere, please tell your boss. If you see a risk, tell your boss. If you're hurting yourself, use your equipment, tell your boss. Don't live with it.

Lastly, know the job site. For the company, some safety issues on equipment. Number one, we talked about, you can design safety upfront, putting it in the right place, or putting the right valves, or putting the hoses in the right place, using the right fittings, using metal fittings instead of plastic.

You've got to fix your serious problems right away.

Check your equipment is secured. If you've got a power sprayer in your truck, or a tool box, or something like that, my suggestion would be, once a year when you take your vehicle to get inspected, or quarterly when you have the oil changed, have someone get under there and just make sure it's attached.

Continuously improve. The same thing I mentioned with the tech, just keep getting your stuff better, steal ideas.

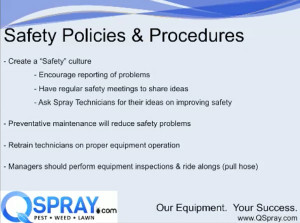

Policies and procedures. This one, it's so easy and we just don't see a lot of people doing it. Create a safety culture. A lot of organizations have a meeting every month where you talk about how to sell more of this kind of work, or that kind of work, or we talk about something that came down from headquarters, but very few companies talk about safety.

It would be so easy, once a month when you're having a meeting, "Does anyone have issues? Anything anyone would want to talk about?" "Here's a safety issue. I went to a meeting and this guy said we should check our equipment before we drive off."

It's so easy. If you're the boss, you've got to encourage your techs to report problems. I've beat that one to death. Have regular safety meetings.

Here's a key one, too. Just because you're the boss doesn't mean you know everything. If you ask your technicians for their ideas, you'll get great ideas, and I don't know why you wouldn't do that. Ask them their opinions. They're the ones using this stuff every day.

Preventative maintenance will reduce safety problems. If you're doing preventative maintenance and you're looking at your equipment, you can prevent chemical spills, you can prevent chemical exposure, you can prevent stuff form coming loose and going flying all over the place.

Retrain employees on proper equipment operation. I know you trained your employees on day one, but that doesn't mean that they're still doing what you want them to do five years later, so you've got to reinforce those procedures with them.

Remember that picture of the guy who was cranking the hose, and it was dragging on the cover, and it was trashing the hose and trashing the cover? I'm sure that guy got trained day one.

Just because you told someone something...Just because I told my five year old kid six months ago not to touch something, doesn't mean he or she is still not touching it. You've got to retrain your employees.

Managers should perform equipment inspections and I really think once a year, once a quarter, once something, ride along with your employees to see what it's like using that equipment. Walk in their moccasins, and get a feel for what that's like, and you can really find some great ways to improve your equipment.

That was my presentation. I just wanted to share one more thing before I open it up to questions. Our experience in doing this for 15 to 20 years is, at least half of all equipment problems are completely avoidable, and we've made a list of those.

You mentioned, you had had it, we made a list of those, and if you go to www.pesttopten.com, you can get a copy of it, download it for free, and I promise you 50 percent of your equipment problems, if you do this, will go away.

If you missed the first videos in the series, please check out those blog posts here:

Spray Equipment Safety Training Seminar Introduction

Rules for Spray Equipment Safety Seminar Discussion

What are the Safety Risk Seminar Topics?

Vehicle Equipment Security: Protecting Your Driver and Others

Vehicle Equipment Security Securing Your Backpack, Gas Can, Hose Reel

Learn Which Vehicle Equipment Areas to Inspect Carefully

A Quick Check Can Keep You Out of Hall of Shame

The Importance of Checking Your Rig and Proper Equipment

Importance of Proper Vehicle Load Stability

How to Avoid Cuts, Burns & Abrasions on the Job

How to Help Minimize Back Strain

Proper Chemical Protection and Cleaning Are So Important

Best Way to Prevent Chemical Leaks

Chemical Spills Due to Hose Issues

You can also check out the slides from the Spray Equipment Safety Seminar here:

For more information on Andrew Greess, visit https://www.qspray.com/