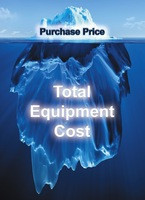

Pest Control Equipment - Purchase Price is the Tip of the Iceberg

Posted by Andrew Greess on Sep 15, 2014

Pest Control Equipment | Pest Equipment | Spray Equipment

Have you ever calculated what your pest control equipment / landscape spray equipment actually costs? Spray equipment cost is like the iceberg; only a small portion is visible. The rest is hiding, waiting to sink your company ship. Don’t assume purchase price is the same as cost.

Total equipment cost is comprised of the following costs:

- Purchase Price

- Installation Cost

- Maintenance Expense

- Repair Expense

- Productivity Impact

- Longevity.

Let’s discuss each component in detail. Note: this article focuses on power spray equipment but the concepts apply to many types of equipment.

Purchase Price is the most obvious component of total cost. Unfortunately, it is often the only cost that is considered in the purchase decision. Purchase price includes total purchase price of the base unit plus any optional equipment, sales tax and freight.

Installation Cost includes the total cost of installing the equipment in the vehicle. Generally speaking, rigs requiring electric power will cost more to install. This equipment must be wired to the truck battery, which takes more time and requires wire, fuse, etc. Be sure to ask your rig vendor if electrical components are included in the purchase price.

Maintenance Expense includes regularly scheduled maintenance, e.g., engine oil changes, pump rebuilds, spray gun rebuilds, etc. Maintenance cost includes the cost of the components and labor. Regular maintenance will extend the life of your sprayer and will prevent unscheduled downtime caused by equipment failure.

We recently serviced a spray rig, in the bed of a John Deere Gator, with a broken engine pull cord. Because of the poor rig design, we couldn’t replace the pull cord without removing the skid from the gator. A five-minute task became a 1-hour job. Think of what this does to maintenance cost if you must remove the rig to perform maintenance. Make sure equipment is designed for ease of maintenance.

Repair Costs. Does the rig constantly break down? Repair cost includes not just the cost of the repair but the downtime that results. Are replacement parts readily available? Waiting for parts can be a productivity killer.

Productivity Impact. Does the equipment boost technician productivity or hinder it? Are key components properly situated for easy, safe, ergonomic access? Must the technician waste perform extra motions just to do her job? (For more on this topic visit www.sprayequipmentblog.com).

Longevity/Replacement Cost. How long do the components last? Are top quality components used?

Two examples.

One of the most expensive components is the gas engine. Honda engines cost more than other engines, but will provide years of uninterrupted service if properly maintained. This is not an area to try to save a few dollars. The higher upfront cost is more than offset in reduced repairs and downtime and extended life.

Some of the cheapest components of your sprayer are the plumbing fittings. Yet these inexpensive parts can cost you a bundle. A plastic fitting in the wrong place can be easily damaged, resulting in chemical spillage and lost productivity. Be sure you know everything you are getting when you order your sprayer.

As professional owners and managers, it is critical to the success of your business that you understand the true costs of your equipment. Learn where your icebergs lie.