Pest Control Electric Hose Reel Wiring Diagram

Posted by Andrew Greess on Sep 30, 2014

Pest Control Hose Reel | Weed Control Hose Reel | Electric Hose Reel

We like electric hose reels for pest control & weed control applications. They make the technician's job much easier by automatically rewinding the hose at the push of a button and reduces the wear and tear on the applicator’s shoulder and elbow from cranking all day. In this post, we’ll explain how to wire your electric hose reel to ensure it runs correctly. But first, there are 3 potential drawbacks to electric rewind hose reels.

1. Cost. Electric hose reels cost more than manual reels and require the additional expense of the electric components. Plan on an electric reel costing about $350 +/- more than a manual reel. If you consider this cost over the life of the reel, this is not much money.

2. Breakdown. Some owners worry that if the reel fails, they have no way to roll the hose back up. This is a legitimate concern. The majority of problems we see with the electric reel are not with the reel itself but with the wiring - that’s why you need to learn how to wire your hose reel properly. Usually, it is a blown fuse. We recommend you carry an extra fuse in the vehicle. Usually, if the reel motor is going to fail, it doesn't fail immediately. It gives you some warning that there is a problem. For example, it winds up slower or makes an unusual noise. You usually have time to address it.

3. Operator error. This occurs more than it should. What we see is the technician doesn't pay attention to what they are doing when rewinding the hose. They let too much hose get on one side of the reel. This can cause the reel to bind up and if not caught soon, can cause the reel hub to wobble out of true. This can be an expensive problem to fix so train, retrain and observe how your technicians use the equipment.

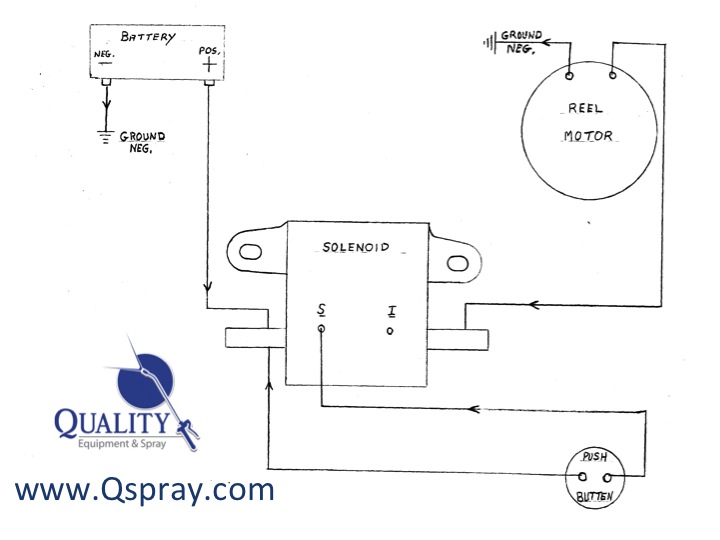

Finally, the point of this long boring post. A lot of folks ask us how to wire their electric hose reel. Here is how we do it:

We use a push button (momentary) switch so the operator can't accidentally leave the switch in the on position. We use a solenoid to protect the motor from an electric surge.

Hope this helps.