Landscape Power Sprayer Design Problems To Avoid

Posted by Andrew Greess on Oct 31, 2019

When you buy inexpensive pest control or landscape spray equipment, you may think you are saving money, but you are not saving anything. You might save some money upfront, but you will more than make up for that cheap purchase price in replacement parts and downtime. We have encountered quite a few design problems over the years and are highlighting a few for you today.

We’ve run into plastic fittings on many tanks. Plastic fittings are cheap and can break when a truck hits a bump causing the contents of your tank to dump all over the place. That could be a big expense and mess to clean up, not to mention more expense and downtime in repair of the tank. Another tank had PVC fittings. While PVC is great for somethings it is not good for sprayer tank fittings.

Plumbing is also a very big issue to look at. We have seen several examples of plumbing going through one tank into another which can cause cross-contamination issues and it is also very difficult to service or repair. When it comes to tanks, you really need to understand the plumbing, and what it means for you when you need to service your sprayer. You want to think about operations and maintenance before you buy.

There are a few other problems we have run into through the years such as thin tube steel tack welds that can easily snap off. Another one required the tech to unroll the entire hose in order to put gas into the pump. He had to do this every day!

When it comes to buying a power sprayer, you want to think operation and maintenance before you make your purchase. Another good thing to do is to get input from your techs and your maintenance team. You want to think about what the equipment will look like in your vehicle.

There are several things to think about before making your power sprayer purchase that will help with your routine maintenance and to reduce your downtime.

Please contact Qspray.com when you need a landscape sprayer or parts.

Andrew Greess : Hello, this is Andrew Greess of Quality Equipment & Spray, Qspray.com. Today we're talking about, power sprayers for your landscape business, or your weed control business, and some of the design problems that you really need to be aware of so that you can avoid them.

These problems cost these companies lots of time and lots of money. These are all examples of sprayers that were brought into us for one reason or another, and we just took photos so we can share some of these key learnings with you.

The first thing to keep in mind is cheap equipment is very expensive. Here's a perfect example. Really, really cheap here. Cheap tank fitting, really cheap elbow, cheap hose, cheap clamp. Every part of this is a risk.

The biggest risk is that, cheap plastic fitting you hit a bump then it will crack. You dump the contents of the tank. It's not worth saving a couple of dollars by using junk like this.

Here's another example of plastic fittings. This one's even worse. You can see we've got plastic fittings here going into the filter. When you crank on that filter, the torque on those plastic fittings is absolutely going to snap those fittings. You're going to be out of business for a while till you can get it repaired. It's also very tight in there.

Here's another one. The bottom right hand portion of this photo is the 200-gallon sprayer that a municipality bought. They actually bought three of these. They went at low bid, kept having problems. They called us, and we obviously didn't win it. I was helping them figure out what the problems were.

I got down on my hands and knees, looked under the sprayer and saw this plastic junk under the sprayer. You can see this is just a couple of hours, with a cheap plastic PVC fittings that are going to break at the first bump, and dump 200 gallons of herbicide all over the streets of this town. Not worth saving money in this place. They should've used good fittings here.

Here's another one. This was just really cheap, thin tube steel that's tack welded. This is a 300-foot, half‑inch hose reel. When that hose is full of water, it's going to weigh 100 pounds. You're going to go bouncing down the freeway or down the road.

These tack welds are just going to snap. You're going to have tons of problems here that hose reel is going to snap right off and hit that engine. Really cheap. You can see the white arrows there where the tack welds are. You got to look for this kind of thing before you buy a sprayer because you won't see this as a problem till, they bite you in the butt.

Next point, plumbing matters. A lot of people ignore plumbing, but it matters. Here's an example. This is the pickup tube inside a tank. You can see it is so tight to the bottom of the tank that as soon as a piece of paper, or any kind of debris gets in there, it's going to clog that pickup tube.

Because your tank is full, you're really going to have a problem. You going to have to get that tank empty or reach through the chemical and clear out that pickup tube. This is really badly built here.

Here's another one. This was a beautiful dual tank landscape sprayer, but whoever built it put plumbing from one tank through the other one. You can see this PVC plumbing comes right through the tank wall. There's no fitting there, just fiberglassed in. When this breaks, this really could be very, very difficult to repair.

The plumbing comes through one tank into the other tank. This is the return. Instead of coming down from the top of the tank, it comes through the other tank. When this PVC breaks and cracks, it's almost impossible to repair. You're going to have cross‑contamination of one tank into the other.

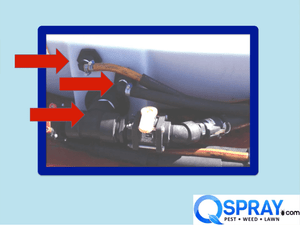

This is a little more complicated, but this is really important. This was 1,000-gallon sprayer that a customer brought to us. The pump was destroyed and the needed just to change the pump, but because of the way this sprayer was plumbed, we couldn't help them.

Starting from the bottom, the bottom arrow shows the suction This is actually plumbed properly to shut off and align. The middle arrow shows the return. The pressure relief is being returned into the bottom of the tank here. That's a really bad idea for a couple of reasons.

One is, diaphragm pump manufacture requires the return going to the top of the tank because, when you do it here, there's two problems. One is you got all that weight and pressure of all that water pushing back on the tank, putting back pressure on the pump, which will void the pump warranty.

Two, because you can't put a shutoff line on the return because if you did, if someone shut it off, it would blow up. We couldn't service the pump, because both this middle line, which is the return of the top line, which is the agitation or below the level of the water. If we took the pump off, the water would drain or the chemical drain down to the level of that tank opening.

Really, really bad design here. This is what we did to repair it. The bottom one the suction was correct. We didn't have to mess with that. The middle one was the return we close that if the client was able to dump the chemical out of the tank. They brought it back, we plugged the return and put the return back into the top of the tank where it belongs.

Then at the top, the agitation we put a shutoff valve so that if the pump ever does need to be serviced, you can shut off this line. Also, as you can see, they're all on brass. It's not the cheap plastic fittings. That's the kind of thing that a lot of people won't notice until it's a problem.

You really need to understand the plumbing, and what it means for you when you need to service your sprayer. You really want to think about operations and maintenance before you buy.

This was a sprayer that was brought in for service. The pump needed service. I'm looking at this thing and I finally asked the technical, "How do you put gas in this thing?" He goes, "Oh man, I have to unroll all three of the feeder hose every day to put gas in it."

Whoever bought the sprayer for this guy, maybe they saved a little money because it was cheap. When you have to unroll three of the feeder hose just to put gas in it, no one's saving any money. That's the kind of thing you have to look for.

Here's another one. This was the sprayer. You can see the arrow's pointing to the hose reel swivel. The hose reel swivel needs service every year. There are small rings in there that need to be replaced every year.

Because of the way this is designed, you can't remove this hose reel swivel without pulling the sprayer out of the truck and either removing the reel or removing whatever this is to the right. What should be a five‑minute job becomes a couple of hours, two‑man job. Just crazy.

Here's another one. This was a customer who hired a new supervisor. The supervisor said, "We have to go buy a sprayer from this other guy, and they did. A couple months later, they brought it in. You can see this is really bad design.

The hose just folded over and cut off the flow to this boomless nozzle. Really bad design that you need to be aware of before you buy a sprayer. Couple of thoughts, you want to think operation and maintenance before you buy. You want to get input from your users and from your maintenance team. You want to think about what the equipment will look like in your vehicle.

Are we going to be able to get everything? Is this going to work? What is it going to be like to use this thing? You want to ask the supplier, "What parts are going to need maintenance? Where do we get the parts? How do we do the maintenance? Who's going to do the maintenance?"

You want to think about these things before you buy them, and before you have a problem. Thanks so much for watching. Please think of Qspray.com calm when you need a landscape, sprayer or parts for your landscape sprayer. Thanks so much for watching.